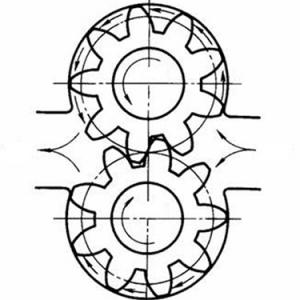

Daily safe operation rules for high pressure gear pump

Daily safe operation rules for high pressure gear pump

1. The oil pump and jack to use the specified number of working oil, generally no. 10 or 20 mechanical oil, can also use other similar nature of hydraulic oil, such as transformer oil.The oil into the tank must be filtered.When in regular use, filter once a month and clean the tank regularly.Generally, 85% oil level should be maintained in the oil tank. When it is insufficient, it should be replenished in time. The replenished oil should be the same as the oil in the original pump.The oil temperature in the tank should generally be 10 ~ 40℃, not in the negative temperature use.

2. Tubing should not bend under working pressure.The oil tank connecting the oil pump and the jack should be kept clean and sealed with screws when not in use to prevent sediment from entering. The exposed oil nozzle of the oil pump and jack should be sealed with nuts to prevent dust and sundry from entering the machine.After daily use, the oil pump should be cleaned, remove oil stains on the copper wire cloth.

3. The oil pump should not work under overload. The safety valve should be adjusted according to the rated oil pressure of the equipment.

4. Grounding power, the chassis must be grounded, and the test operation can only be conducted after the insulation of the circuit is checked.

5.High pressure gear pump before the operation, should loosen the oil regulating valve, and then start the oil pump, to empty load normal operation, then close the return valve, gradually screw into the oil valve stem, increase the load, and pay attention to whether the pressure gauge pointer is normal.

6. When the oil pump stops working, the return valve should be slowly loosened first. After the pressure gauge slowly returns to zero, the oil pipe joint nut of jack can be unloaded.Do not remove or replace the tubing or pressure gauge when under load.

7. It is advisable to adopt double oil pump with double action jack.

8.oil resistant rubber hose must withstand high pressure, the working pressure shall not be higher than the high-pressure gear pump rated oil pressure or the actual work of the maximum oil pressure.The tubing length should not be less than 2.5m.When one oil pump drives two jacks, tubing specifications should be the same.