How to eliminate hydraulic pump (piston pump vane pump gear pump) trapped oil phenomenon?

How to eliminate hydraulic pump (piston pump vane pump gear pump) trapped oil phenomenon?

1) hydraulic pump trapped oil phenomenon

The closed volume of hydraulic pump is formed in the process of transferring to the pressure chamber after filling up with oil.If the size of the deadlocked volume changes, when the deadlocked volume changes from large to large, the oil is squeezed and the pressure rises sharply, making the bearing subject to periodic pressure impact and resulting in oil heating.When the closed volume changes from small to large, vacuum is generated due to the absence of oil replenishment, which causes cavitation erosion and noise.The phenomenon of pressure impact and gas erosion caused by the change of closed dead volume is called trapped oil phenomenon.

Oil trapped phenomenon will seriously affect the service life of the pump.In principle, the hydraulic pump will produce trapped oil phenomenon.

2)the hydraulic pump trapped oil phenomenon harm

The phenomenon of oil trapped in hydraulic pump is very harmful.Because the compressibility of the oil is very small, and the trapped oil area is a sealed volume, after the trapped oil is squeezed, it will be forced to extrude from the cracks on the mating surface of the parts, which will subject gears and bearings to a great amount of additional load, generate power loss, and also make the oil temperature rise.When the volume of the trapped oil area increases, a local vacuum will be formed in the trapped oil area, the gas in the hydraulic oil will be precipitated, and the oil gasification will produce bubbles, which will enter the hydraulic system and cause vibration and noise.In addition, also reduce the pump flow, resulting in instantaneous flow volatility increase.

3)How to eliminate the phenomenon of oil trapped in hydraulic gear oil pump?

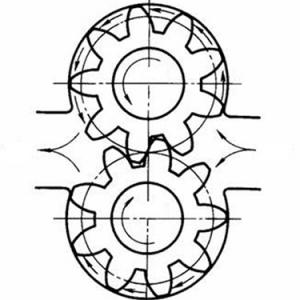

During the meshing process of external gear pump, in order to keep the gear running smoothly and continuously sucking and pressing oil, the ¦ A of gear coincidence degree must be greater than 1, that is, before the first pair of gear teeth disengage from meshing, the second pair of gear teeth have entered meshing.When two pairs of teeth engage at the same time, a closed volume is formed between them.With the rotation of the gear, the closed volume first decreases, then increases from small.So the gear pump is trapped oil phenomenon.

In order to eliminate trapped oil phenomenon, unloading groove is often opened on the front and rear cover plate of the pump or floating axle sleeve (floating side plate), so that the closed dead volume limit is the minimum. The volume is connected with the pressure oil cavity from large to small, and the volume is connected with the oil absorption cavity from small to large.

4)How to eliminate oil trapped in hydraulic vane pump?

In the acting vane pump, although there is a closed dead volume between the suction and pressure oil distribution Windows, the volume does not change, so there will be no oil-trapped phenomenon, because the Angle between the stator arc and the oil distribution window is > and the Angle between the two blades is >.However, because the arc curve on the stator and its center Angle are not very accurate, there may still be a slight oil trap.In order to overcome the harm of oil-trapped phenomenon, a triangular slot with triangle section is often opened at the front end of the oil pressure window of the oil distribution plate, which is also used to reduce the pressure mutation in the oil cavity and reduce the pulsation and noise of the output pressure.This groove is called vibration damping groove.