Description

The FUH series of engineering plastic pumps are a project introduced by the former Ministry of Chemical Industry and a major national scientific and technological achievement during the "Seventh Five-Year Plan" period. They were meticulously designed based on the digestion and absorption of imported equipment and in combination with the structural advantages of domestic corrosion-resistant centrifugal pumps. This series of pumps was included in the National "Torch Program" in 1993 and won the New Product Award in 1995.The flow-through components of this series of pumps are made of ultra-high molecular weight polyethylene (UHMWPE), which has excellent corrosion resistance, outstanding wear resistance (ranking first among all plastics), and strong impact resistance. The pump's seals adopt various sealing forms such as mechanical seals, dynamic seals and packing seals. It can not only transport acid and alkali clear liquids, but also slurry containing solid particles and wastewater with various impurities. Especially in transporting corrosive liquids containing fine particles and hydrofluoric acid, fluosilicic acid, phosphoric acid, mixed acids, electrolytes, hydrochloric acid, dilute sulfuric acid, concentrated alkali, etc., it shows excellent performance.

This pump is suitable for temperatures ranging from -50℃ to 100℃. After replacing the impeller and pump body with other engineering plastics (polyvinylidene fluoride PVDF, perfluoroethylene-propylene copolymer F46, random copolymer polypropylene PPR), the applicable temperature can reach 120℃. This pump can be equipped with duplex steel, 904 or 304 stainless steel impellers. FUH series pumps are horizontal, single-stage, single-suction, and bracket-type centrifugal pumps.

Properties

Outlet diameter: 25mm - 80mm

Flow rate: 3.6m³/h - 100.8m³/h

Head: 13m - 120m

Suction power: 0.713kw - 14.73kw

Speed: 2900r/min,1450r/min

Submerged length: 500mm - 2500mm

Motor power: 1.5kw - 1000kv

Material:

Medium temperature: 20℃~120℃

Pressure:1.6Mpa

Feature

1.FUH all-plastic corrosion-resistant and wear-resistant pump is mainly applied to various liquids such as acids, alkalis, salts, oils, food and beverages, and alcoholic beverages.

2. It is specifically applied to various clear liquid or slurry positions of sulfuric acid, salt, acid, alkali, oil, etc. in the chemical industry.

3. In the non-ferrous smelting industry, especially in the hydrometallurgical processes of lead, zinc, gold, silver, copper, cobalt, tungsten, rare earths, etc., various media such as acid solutions, ore slurries, slurry (used in filter presses), electrolytes, and wastewater;

4. Media such as dilute acid (for pickling process), mother liquor, hydrofluoric acid, fluosilicic acid, seawater and phosphoric acid slurry in the fertilizer industry;

5. Various types of wastewater in the water treatment and environmental protection industries (such as food wastewater, electroplating wastewater, leather wastewater, pharmaceutical wastewater, papermaking wastewater, textile wastewater, electronic wastewater, etc.) and desulfurization and dust removal;

6. Sulfuric acid and salt acid positions in the pickling system of the steel industry; Acid hydrolysis, sedimentation, freezing, hydrolysis, water washing and salt treatment in the titanium white powder industry; Acid stations in the chemical fiber industry

7. Positions such as fermentation, neutralization, filtration, wastewater treatment of citric acid, and the manganese industry of ferrous metals, etc.

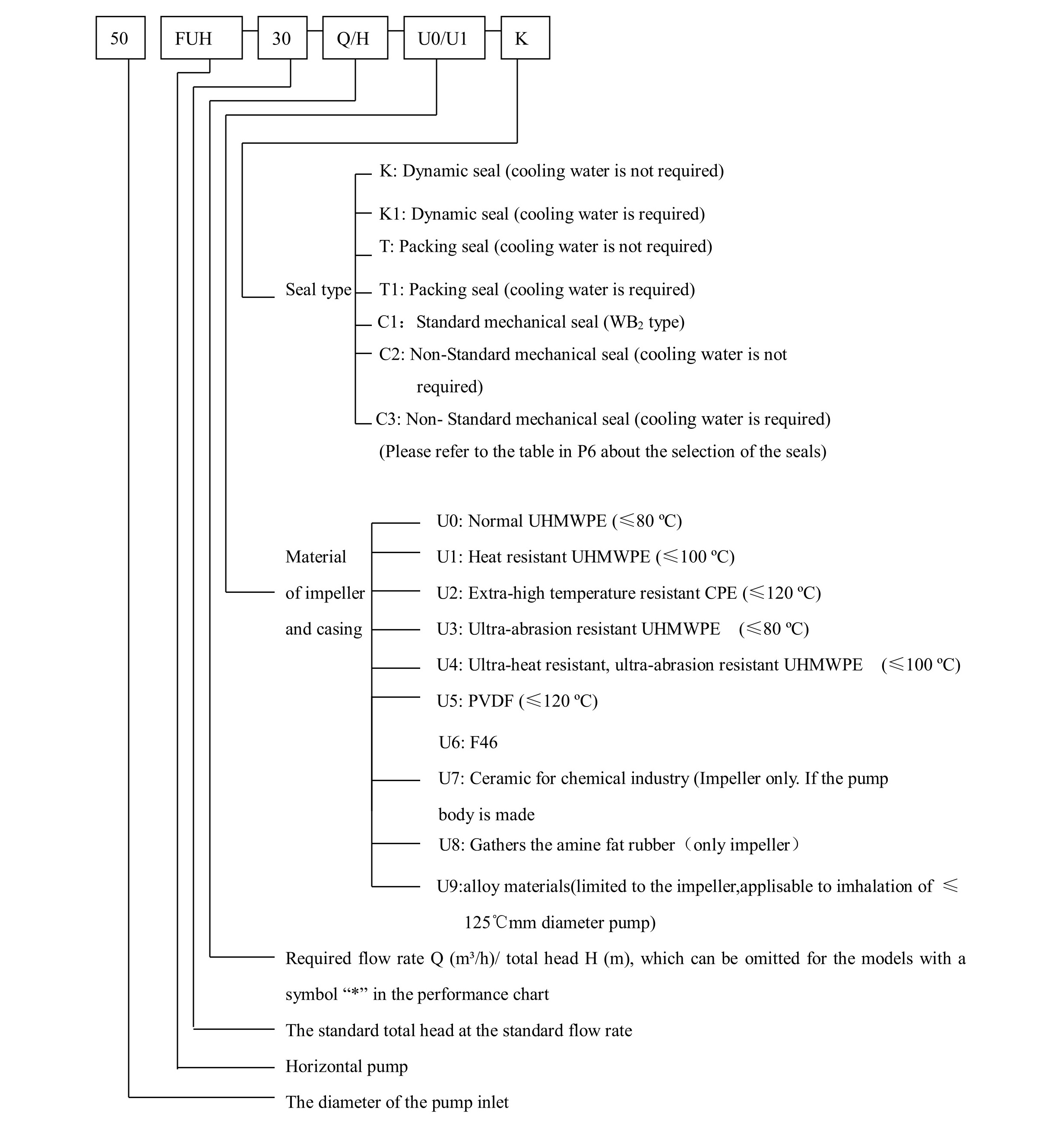

Model Code

Technical Specification: